There’s no doubt that rooftop solar and home batteries are a bloody good combo. Not only does solar allow households to make a contribution towards the fight against climate change, but it can help homeowners take control over their energy supply and avoid skyrocketing power prices. And once panels produced by Natural Solar’s parent company 1KOMMA5° hit the Aussie market later this year, homeowners will have the added peace of mind that their solar modules were produced efficiently and humanely.

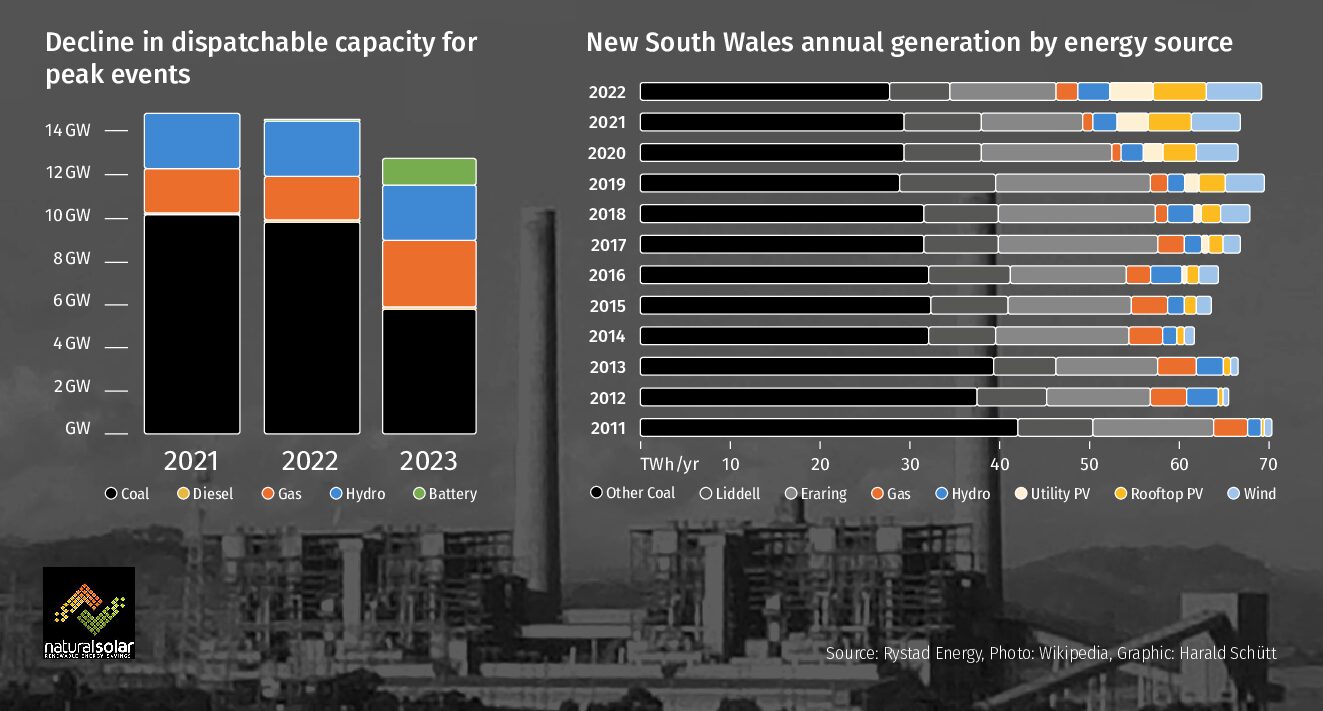

Given its virtues, the last decade has seen Aussie homeowners adopt solar at world-beating rates – so much so that solar is increasingly beating coal as the leading power generation source in the Australian grid.

But there have also been some questions raised recently about where and how the bulk of the solar panels are made. Some worry that if solar panels, and their component parts, are being produced using polluting power sources then the PV industry will be contributing to the problem it is working to solve.

There have also been concerns raised that some solar products may be produced using workers from the Xinjiang region in China – where there have been reports of forced labor practices. The ethnic minority Uyghur people are the subject of forced labor programs, and there have been links between some solar manufacturers and these programs.

And then the wider geopolitical situation is a cause for concern. We’ve all seen how, in this increasingly connected world, conflict in one region can trigger impacts all over the world. The invasion of Ukraine by Russia being the prime example of this, leading to the world’s first global energy crisis – and the high electricity prices soon to hit Aussie homeowners.

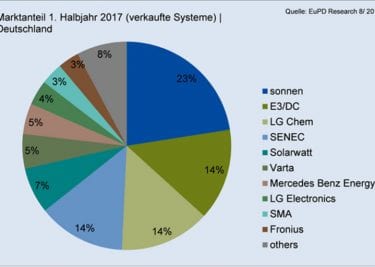

Tensions between China and the United States are rising. Today, China is far-and-away the world’s largest producer of solar panels. In fact, the country has so adeptly captured the solar panel supply chain that it produces upwards of 97% of solar wafers – the building blocks of a panel.

Doing it ourselves

Given these dynamics, the team at 1KOMMA5° took the bold step to begin producing and supplying our own solar modules for our customers. Natural Solar was welcomed into the 1KOMMA5 family in October 2022, and we look forward to supplying our Full-Black solar modules to Aussie homeowners as soon as this spring.

But establishing a solar manufacturing operation is not something that can be done overnight. There are many stages to the solar manufacturing process, and 1KOMMA5° will begin by tackling the production steps where the most impact in terms of environmental, social, and security-of-supply can be achieved.

As an initial step along this journey, 1KOMMA5° has contracted with German polysilicon producer WACKER to secure enough of the raw material to equip 25,000 homes with solar systems in the first year alone. Polysilicon is the material from which solar wafers, cells, and eventually panels is made.

WACKER is an expert in producing polysilicon, and by securing a big supply of high-purity “poly” from the company, 1KOMMA5° can ensure that it’s modules are produced in an energy efficient way.

Speaking to the media at the announcement, 1KOMMA5° founder Philipp Schröder explained how WACKER poly means more energy-efficient modules. “The savings are from efficiency, and also since Germany’s energy mix, especially electricity, is almost 50% renewable energy and WACKER has focused on clean energy very early on.”

The polysilicon produced in China, and in particular Xinjiang, has also been in the crosshairs of regulators recently. In the United States, shipments of solar panels have been stuck at the border, as US Customs officials detain them on suspicion of having been made with polysilicon tainted with forced labor. The situation has left solar companies waiting many months for modules, and the US solar market declining, while elsewhere in the world it expanded.

With the recent WACKER deal, and the plans to ramp up factories in Germany to produce its All-Black PV panels, 1KOMMA5° is making sure this won’t happen to its European or Australian customers. And these customers can rest easy knowing that their solar panels are produced in an energy efficient way, and free from forced labor.

Manufacturing plans

Looking more closely at the manufacturing plans of 1KOMMA5°, it’s clear that the company is taking a sensible approach to supplying high efficiency solar panels to its customers. As a first step, the All-Black module was developed – which has an efficiency of 21.5% and will come with a 25-year manufacturer warranty.

Secondly, the WACKER “poly” deal will keep the supply chain clean and ensure 1KOMMA5°, Natural Solar and our customers are doing a good thing by installing solar, but also doing the right thing by ensuring the panels on their roof are made in an energy efficient and humane way.

The brains behind 1KOMMA5°, Philipp Schröder, said that while the first batch of production will take place in partnership with a “tier one” manufacturer in China, that moves are already underway to relocate production to Germany.

“We are in negotiations with contract manufacturers to move production completely to Germany with the latest TOPCon generation,” said Schröder. “The site search has already begun.”

Schröder says that the site should be selected by the end of 2023, with production beginning in late 2024 or early 2025. Instead of going it alone, 1KOMMA5° will likely partner with an existing German PV panel producer, to leverage their expertise on the factory floor.

It is a straightforward strategy to deliver clear benefits for solar homeowners. And when coupled with powerful technology like the 1KOMMA5° Heartbeat Energy Manager, efficient, low carbon, and ethical All-Black modules will make a compelling proposition to Natural Solar customers.